Automatic Laundry Management System

Automatically track and manage laundry activity

Complete Laundry Management System

For laundries, hospitals, care facilities and the healthcare sector, supplying employees with workwear, pool laundry and uniforms is often a challenge.

deister’s laundry management system uses RFID technology to effectively manage commercial linens, mats or garments, optimizing inventory and reducing human error in washing and management processes.

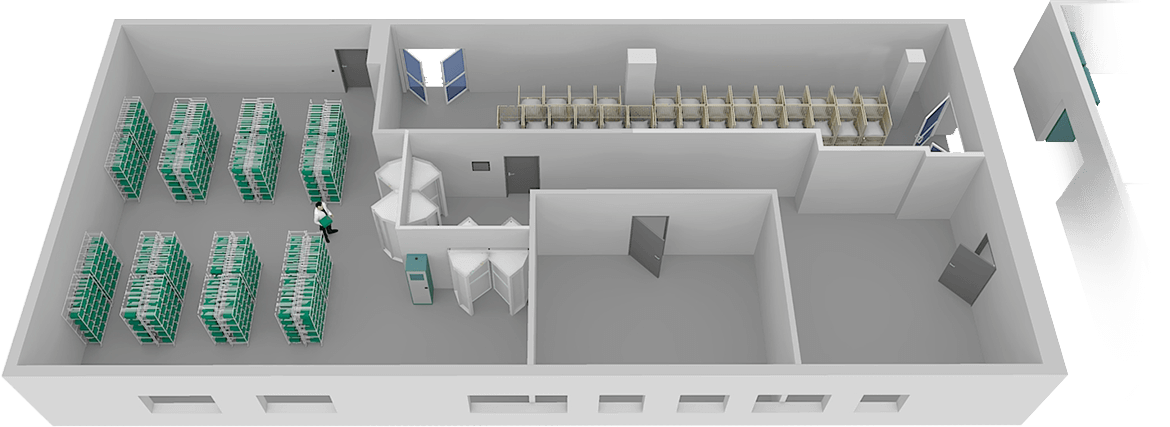

The intelligent cabinets (automatic dispense and return of garments) enable decentralized distribution and reduce time spent by employees to get new laundry. Individually planned room solutions function like a walk-in wardrobe. When entering and leaving the supply room, the clothing of the employees in the revolving doors or airlocks is automatically recorded and accounted for.

Fast Access

Retrieve your garments in under 5 seconds. Simultaneous user access.

Eliminates Losses

Eliminates 99% of unaccounted losses associated with daily laundry activity

Work Smarter

Accurate inventory tracking and process improvements

Improve Labor Productivity

Delivers greater labor productivity. It eliminates manual tasks and automates record keeping.

Reduce Purchases

Cuts annual purchases. Laundry System knows what items to replace to maintain quality standards.

Enhances Customer Relations

Provide better information to your customers and eliminates discrepancies and disputes

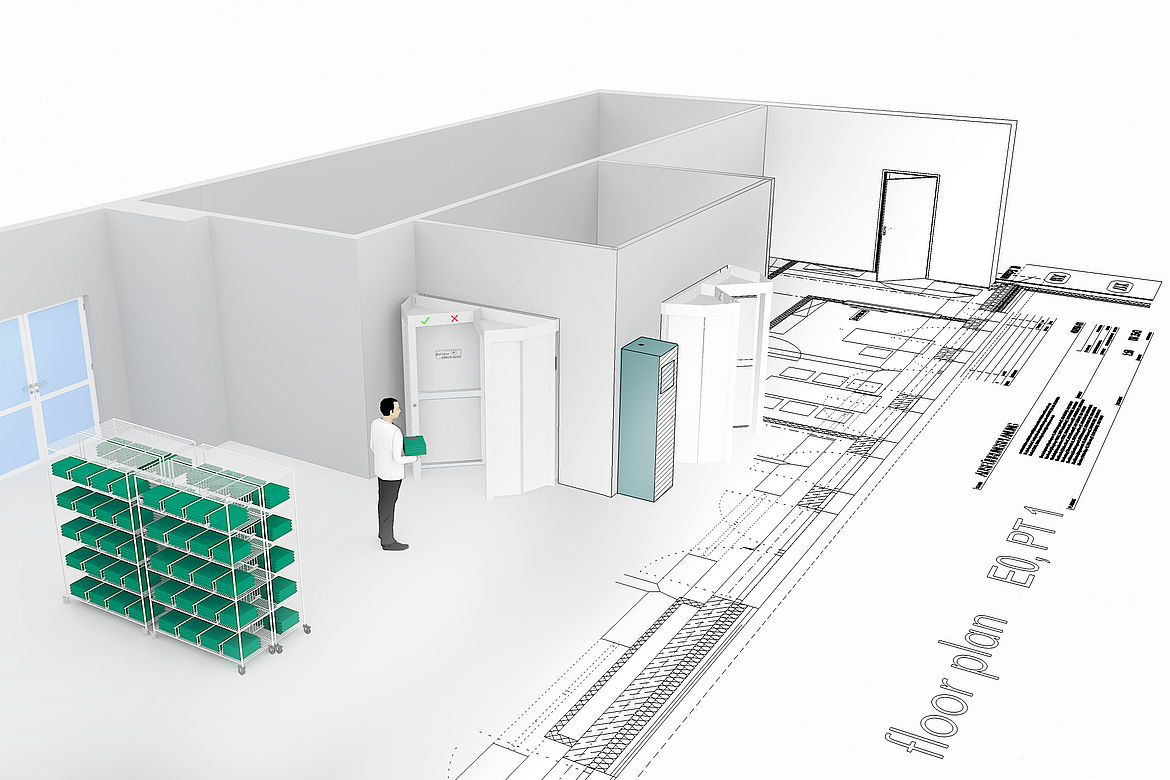

texRoom Solution

The texRoom solution is individually planned and functions like a walk-in wardrobe. Entry and exit is granted through intelligent revolving doors or a gate, which automatically identify the garments taken by the wearer as well as the delivery of new garments. The room solution focuses on efficient and reliable detection of wearers and garments, as fast and efficient output is particularly important for many wearers in order to avoid waiting times and delays.

The laundry is simply returned using the return cabinets, which are placed in logistically sensible locations. The wearer simply deposits his laundry there and it is automatically accounted for accordingly.

The removal of new clothing is quick and easy: the wearer identifies himself with his ID card at the revolving door and enters the supply room, takes the desired clothing and leaves the room again through the revolving door – the removed clothing is automatically recorded and accounted for in the revolving door.

- Simplest operation: wearers only have to identify themselves by ID card at the revolving door or gate, the garment detection is fully automatic as they pass through.

- Extremely short process time: Garment acquisition is fast, parallel and uncomplicated

- Permanent inventory – 24/7 overview of textile inventory in real time

Dispense Cabinet

The laundry dispenser cabinets are designed for quick access. Simply hold your ID card in front of the reader integrated in the door handle and remove the laundry in less than 5 seconds. Access permissions are easily managed by our software.

Return Cabinet (small)

To return laundry, the user simply drops the laundry pieces into the opening of the return cabinet. The laundry is automatically identified by the cabinet. When the cabinet is completely full, the garment bag inside can be changed quickly and easily.

Return Cabinet (Large)

With the large TCR 250 laundry return station, up to 300 textiles can be returned. The return system is designed for all common laundry trolleys and is ideal for large systems with high circulation rates.

Smart Transponders

Each garment is labelled with a UHF transponder. This electronic identification enables the automatic management of clothing and documentation of its life cycle.

textag UHF transponders can be programmed with individual data, such as colour, size, washing temperature, date of purchase, etc. All data stored in the textag transponder is encrypted and thus protected against manipulation. The 128-bit EPC data record enables maximum performance when scanning containers.

The tags withstand compression, exposure to detergents and chemicals, and the high temperature requirements of laundry and sterilization processes.

Manage with a Click of a button

Laundry management, allocation and administration of the wearers can be easily implemented with the Commander Connect software. The Commander Connect software offers a transparent overview of the laundry and garment stock at all times and you have an immediate overview of the life cycle of the garments.

The contents of all dispensing and return cabinets as well as the inventory of the room solution are always accessible. This way, the inventory can be clearly optimized and availability guaranteed.

Consulting and Planning

From the delivery and distribution of clean clothing, to the return and cleaning of used garments in the laundry – we will be happy to support you in the individual planning and implementation of a laundry dispensing system that exactly fits your needs and allows for transparent management.

Our focus is on maximum user-friendliness, reliable identification of garments and wearers and very low space consumption of the system.

Experience

Experience the user-friendliness and performance of our laundry output solution live in our demo room. Here you can operate and test all products and applications of the solution yourself.

Please feel free to make an appointment for a free consultation and demonstration.